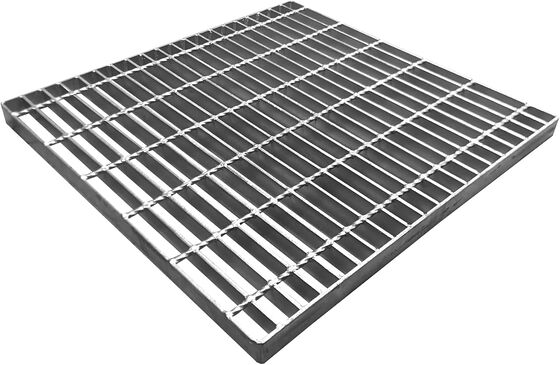

As grades em barra de aço são conhecidas por sua estrutura robusta e de alta resistência, fabricadas em aço carbono, alumínio ou aço inoxidável. Disponível em quatro tipos de produção (barra soldada, grade travada por pressão, travada por estampagem e grade rebitada) com opções de superfície lisa ou serrilhada. Esta solução versátil atende inúmeras aplicações, incluindo degraus de escadas, passarelas, plataformas, pisos, coberturas de valas, equipamentos com rodas, telas de segurança e construções pesadas.

Especificações Técnicas

Materiais:

Q195, Q235, Q235B / 304, 316 Aço Inoxidável

Barra de rolamento:

25×3, 25×4, 25×4,5, 25×5, 30×3, 30×4, 30×4,5, 30×5, 32×5, 40×5, 50×5, 65×5, 75×6, 75×10-100×10mm etc; Barra I: 25×5×3, 30×5×3, 32×5×3, 40×5×3 etc.

Padrão dos EUA: 1"×3/16", 1 1/4"×3/16", 1 1/2"×3/16", 1"×1/4", 1 1/4"×1/4", 1 1/2"×1/4", 1"×1/8", 1 1/4"×1/8", 1 1/2"×1/8" etc.

Passo da barra de rolamento:

12,5, 15, 20, 25, 30, 30,16, 30,3, 32,5, 34,3, 35, 38,1, 40, 41,25, 60, 80mm etc.

Padrão dos EUA: 19-w-4, 15-w-4, 11-w-4, 19-w-2, 15-w-2 etc.

Passo da barra transversal torcida:

38,1, 40, 50, 60, 76, 80, 100, 101,6, 120mm, 2" e 4" etc.

Classe de aço:

ASTM A36, A1011, A569, Q235, S235JR, S275JR, SS304, aço macio e aço de baixo carbono etc.

Tratamento de Superfície:

Preto, cor própria, galvanizado por imersão a quente, pintado, revestimento em spray

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!